Gates

Ornate Gates

Middleton Forge can manufacture a gate to suit your exact requirements. Because we manufacture in-house, these can be as simple, or as detailed as you require. Our huge range of components on offer allows you to create the exact design you require.

Here are a few examples of previous gates we have manufactured.

Butler

Ornate gates manufactured exactly as the client's requirements

Woodland

A basic rectangle frame, vertical infill with arrow head finials. We have used a box section frame, larger tubular infill bars and heavy arrow heads to help create a grand looking gate.

Wemmergil

The rises at each end of the gate and the solid middle rail create this unique design.

Wemmergill

A simple design, just enough features to blend into place.

Wemmergill

This particular location required a intercom system

Teesdale

By adding two middle rails and extra lower vertical bars we create our "Teesdale" range. We supplemented this design with circles to infill between the two rails and a row of scrolls under the top rail.

Teesdale - 'Heather'

A simple "Teesdale" design. These gates were left with a galvanised finish and are as good today as when fitted over 15 years ago.

Teesdale - Eagle Riggs

Creating a variation of the Teesdale we have replaced the row of circles for letters.

Stonechester

A large, bold design.

Sonechester

The Circle and name create this distinctive design

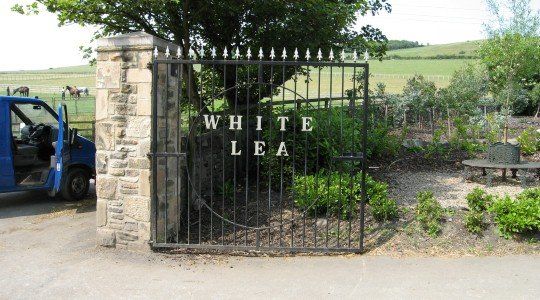

White Lea

Another variation

Sedgefield

By applying an arched top we have created our "sedgfield" range.

Sedgefield Leaf

Photo's to follow of the make up

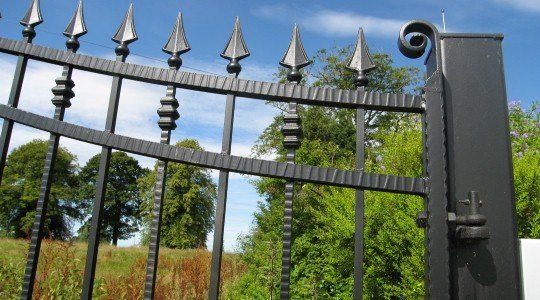

Sedgefield

Attention to detail - smooth welds. One of many finial choices.

Basekt

A basket welded into hammered bar. The welds are camouflaged with steel decorative banding. Hammered box section and a hammered decorative clashing strip are on the left.

Sedgefield

Slightly different variation

Sedgefield

The gate in its galvanised finish. Preparation and checks are made before the gate goes to be powder coated.

Sedgefield

Design includes finials, collars baskets and circles

Sedgefield

The automated gates have been projected between the stone pillars. All the automation is now hidden.

Saltholme

Created exactly as the architect required

Ropner

Vertical bar gates with a bit of extra finishing detail

Pre installation

For a new opening, we can manufacture the gates ready just to be dropped into position.

Nunthorpe

Ornate in their own right

Nunthorpe

Attention to detail. Hinges, latch, dropbolts and material selection.

Newbiggin

In a rural location, the client wanted strong steel gates, but to look like wooden gates.

Newbiggin

Box section blended into tubular steel created the desired effect.

The Hude

Similar to the "Newbiggin" but the gate is constructed from a box section frame and infill horizontal rails, with the diagonals and verticals made from flat strip welded to the front face.

Holwick

Using a heavy box section frame creates a quality product. Middle rail, extra arrow heads, twisted verticals and baskets create this design.

Holwick bi-fold

Due to minimal space we manufactured these gates as "bi-fold" gates. This allows a wide opening to be closed with gates that when hinged and swung take up minimum space.

Holwick

Hooks have been drilled and resined into existing stonework.

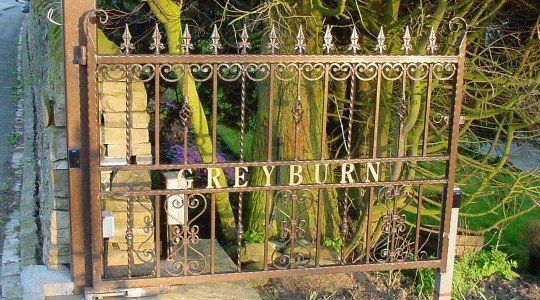

Greyburn

Steel letters have been welded into the middle rails; twisted verticals applied; hammered box section frame, lower scrolled panels, solid steel collars and steel baskets. Note the underground motors.

Eggleston

A simple - bold design

Eggleston

A square design made up of box sections and tubes.

Durham

A simple, elegant gate. The design feature is the solid verticals with a squashed end.

Cotherstone

A design feature top and bottom of the gate, with a centre piece.

Cotherstone

Double leaf option.

Circles

A simple row of circle's. One of many arrow head finial choices.

Collars

Square collars sit between the double top rails.

Built in hinge

Keeping the stone pillar as a design feature, the hinges have been built into position.

Sliding gates

Sliding gates are manufactured in two ways, Tracked method, and Cantilever method. At Middleton Forge we manufacture and install both of these types of gate.

Tracked method is basically a wheeled gate, held in the vertical position by a post, but slides along a steel track set into concrete.

Cantilever method is a gate with a channel welded to the bottom of the frame. By using a series of guides and balancing, this method avoids the need for any ground tracking and the additional maintenance associated.

Middleton Forge manufacture and install a wide range of sliding gates. They are designed to suit your individual requirements. While perfect for heavy industry, we have also carried out installations on many domestic properties and smaller commercial installations.

Mesh sliding

A neat example showing the track in the open and closed position.

Woolfe

A sliding & hinged combination. The gates are steel frames with timber infill.

Sapele

Pedestrian gate complements the design

Sapele

Galvanised steel frame, Sapele infill

Peebles

A simple but very effective rural design

Peebles

The toothed rack running along the inside of the gate.

Peebles

The octagonal shape in the induction loop which allows the gate to open when a vehicle is passes.

Palisade

Sturdy box section frame, clad with palisade pales.

Palisade

The palisade gate blends nicely in amongst the matching fence.

Palisade

The profiled wheel runs smoothly across the domed track.

MF

Strong box section outer frame with fully welded box section infill

MF

A 7.5m opening is now securely closed.

Cantilever Sliding Gate

Killingworth Leisure Centre

Evenwood

A heavy duty cantilever filled with 200 x 50mm twin wire mesh and backed with high voltage electric fencing.

Evenwood

Lifted into place and bolted down to pre cast concrete slabs.

Evenwood

The gate is delivered & fitted as one unit. The complete service provided by Middleton Forge.

Evenwood

Note the electric fence wire strands running through the black insulators.

Evenwood

A heavy duty motor to drive the gate.

Crook

Sliding gates are available in all shapes and sizes.

Crook

A pin code entry system was applied to this automated gate.

Crook

Fully welded box section design.

Cramlington

Two cantilever gates brought together to cover a larger entrance.

Cramlington

Both gates meet on the centre support.

Cramlington

Operative checking the large gate rides up onto a centre support.

Cramlington

To allow for the sloping opening, the LH side of the get is projected above ground level.

Benfield

Another mesh example. Note - One third of the gate is supported with the rollers while the remaining two thirds is suspended.

Benfield

A level opening is to be considered.

Hinged Gates

Hinged gates are the most common type of steel gate we manufacture.

Our range includes:

- Vertical Bar gates

- Vertical Tube gates

- Mesh Gates

- Timber Clad gates

- Ornate gates (see separate pages)

Vertical box

Using box section creates a heavy, traditional look

Vertical box

Heavy duty slide bolt system

Vertical bar

Box section frame, vertical bar infill

Vertical bar

Purpose built to do the job.

Vertical bar

Designed around the fence.

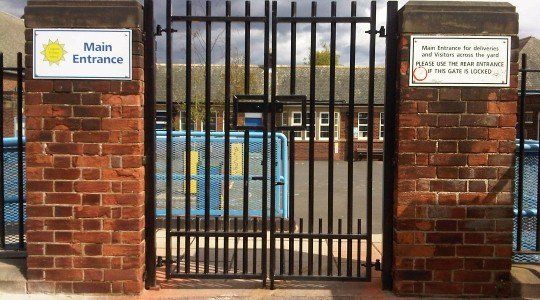

Vertical bar

Dropbolts to be locked into position. Ideal for schools.

Vertical bar

Closes above the kerb out of harms way.

Timber boarded

A steel frame is applied behind the timber boards

Timber boarded

Minimal gaps in this bin store.

Timber boarded

The hidden galvanised frame

Site mesh

We manufacture temporary site gates

Sapele

A galvanised frame with a Sapele infill

Sapele

Strong and effective

Pitch gates

We manufacture a range of gates for use on various sports pitches

Ornate

See our Ornate section for other styles we offer.

Mesh security

50 x 50 x 4mm weld mesh creates an ideal security solution.

Mesh security

These gates were backed with high voltage electric wires.

Kissing gate

A bespoke "kissing" gate arrangement

Key entry

Key entry systems can be added if required

Heavy duty

We even manufacture our own Heavy Duty eyebolts

Mesh automated

We can automate all our gates

Gate Automation

Middleton Forge can not only offer tailor manufactured gates, but we can also carry out your gate automation requirements.

We carry out all kinds of installations for domestic, commercial, agricultural and industrial clients.

We can also offer advice to help you choose the correct access control method, which may include:

- Remote Key Fobs

- Timers

- Keypads and intercoms

- Induction Loops

- Push buttons

Underground motor

Placed underground on the inside of the property. A very neat & tidy option.

Tracked motor

A tracked motor operates sliding gates. We even offer 3 phase options for heavier installations.

Plug & play

We can manufacture, automate & Hi-ab deliver the whole kit.

Want to find out more?

Leave us your info, and we’ll get right back to you.

Sign up to our newsletter

We will get back to you as soon as possible

Please try again later